With Trivolt’s SOS Service, we can expedite delivery of select heating elements within as little as one week, minimizing your downtime and keeping your operations running smoothly!

Our website uses cookies. By continuing to browse our site you are agreeing to our Cookie Policy.

Cost-effective and environmentally conscious

Ideal Gas & Liquid Temperatures During Transportation, Processing and Storage.

In partnership with Trivolt, we offer engineered equipment solutions for all your needs.

We have partnered with Trivolt, a leader in providing innovative solutions for maintaining ideal liquid and gas temperatures during manufacturing and transportation. We understand the challenges you face in finding cost-effective, environmentally conscious equipment for liquid and gas processing, storage, and transportation.

We also offer Trivolt's new line of NOFREEZE products to prevent pipes, flow meters, and transmitters from freezing.

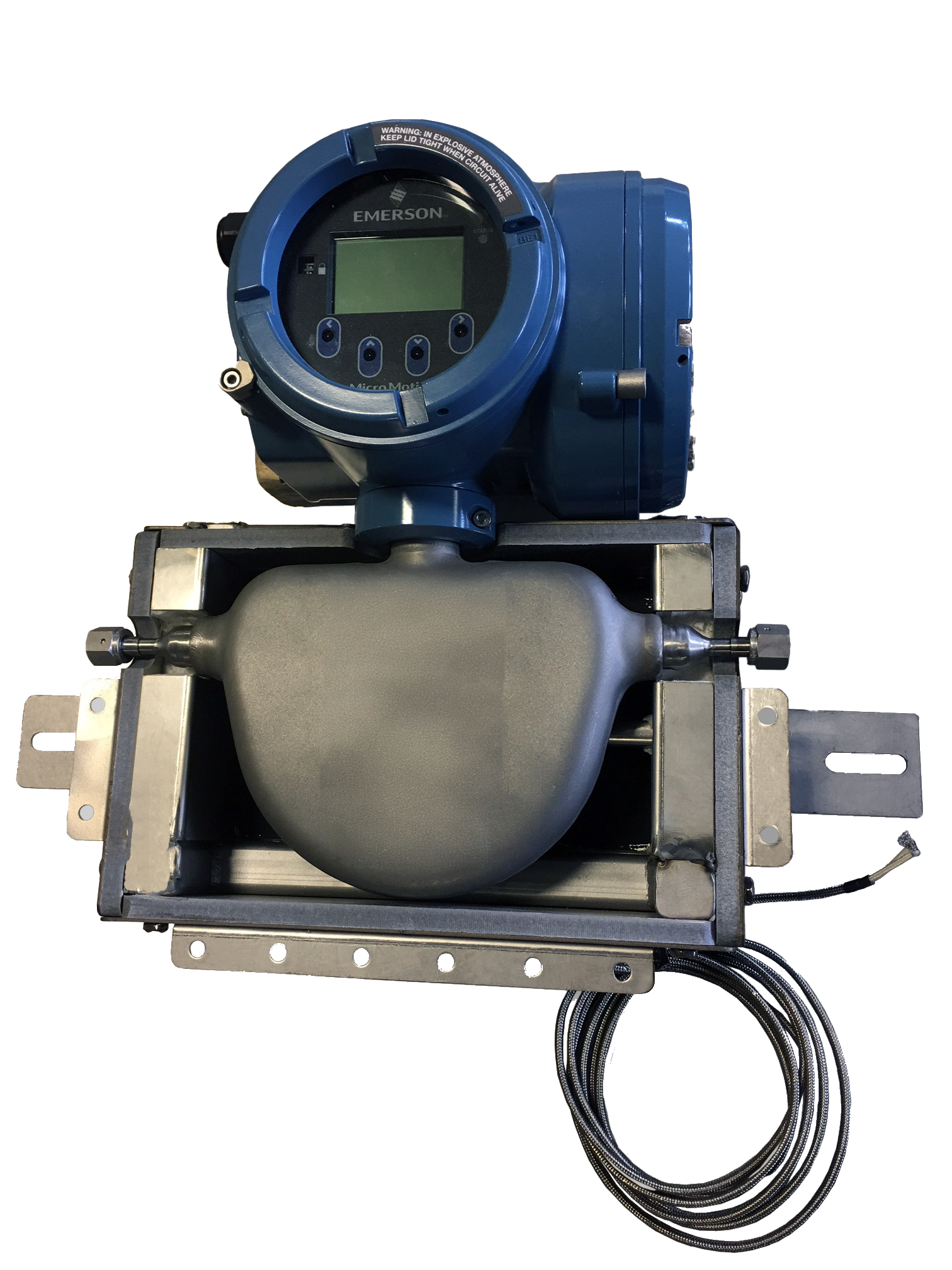

NOFREEZE Featured Product

Trivolt's new suite of products to prevent pipes, flow meters, and transmitters from freezing.

Triflex Block

The Triflex Block is designed for transmitters, flow meters, and any other product that aids in critical temperature control management. The Triflex Block is part of the NOFREEZE product suite, which is designed to prevent the freezing of pipes, flow meters, and transmitters.

Key Features:

Key Features:

- Versatile Material Options: Available with controls and NEMA 1, 4, 4X & Explosion proof

- Innovative Design: Ensures precise temperature management with a deviation of +/- 4°F

- Wide Range of Applications: Suitable for transmitters, flow meters, and other critical temperature control products

- High Efficiency: Built to meet the specific heating needs of various industry verticals

- Compliance and Certifications: NEMA compliant and explosion-proof options available

Featured Products

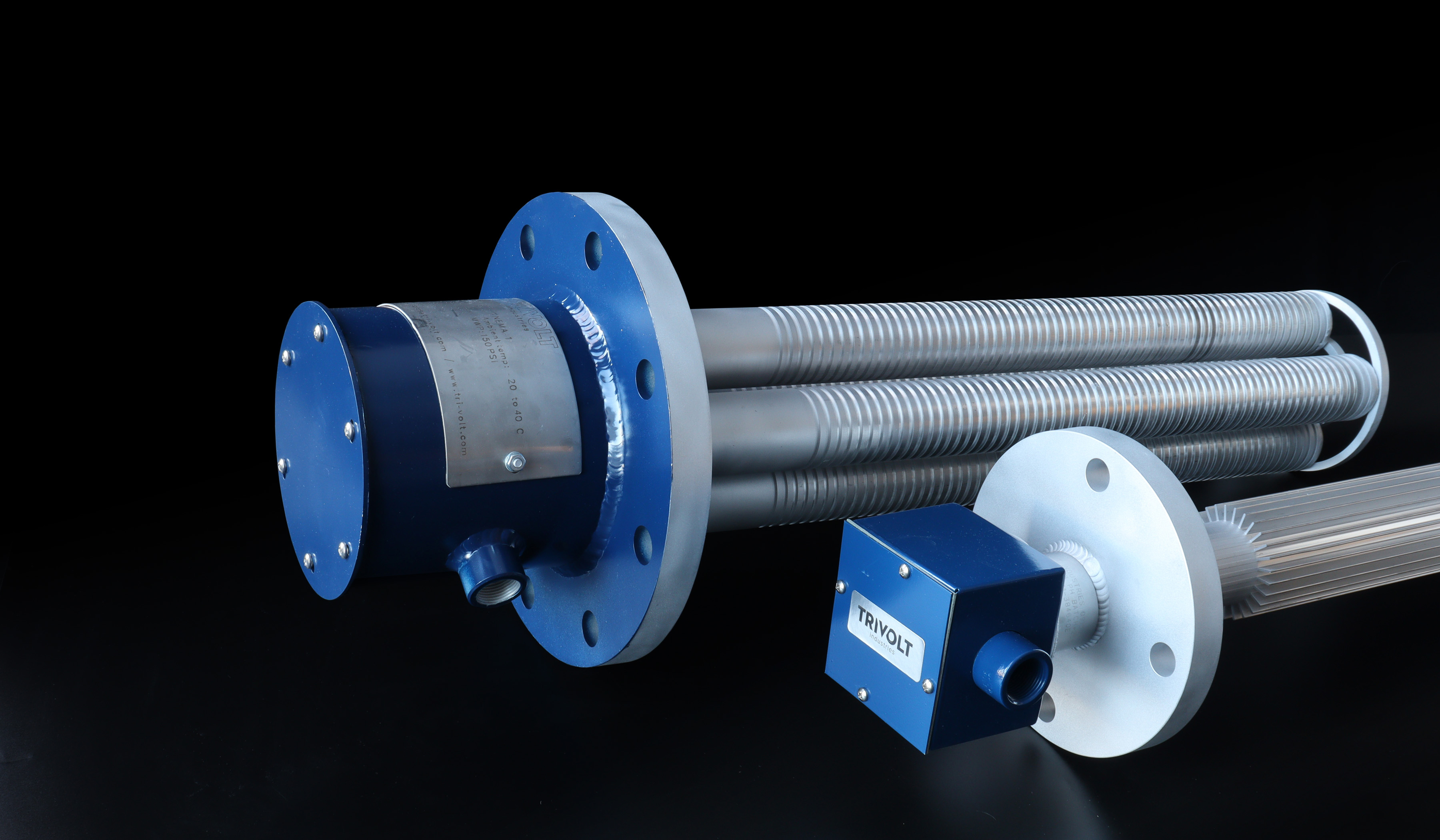

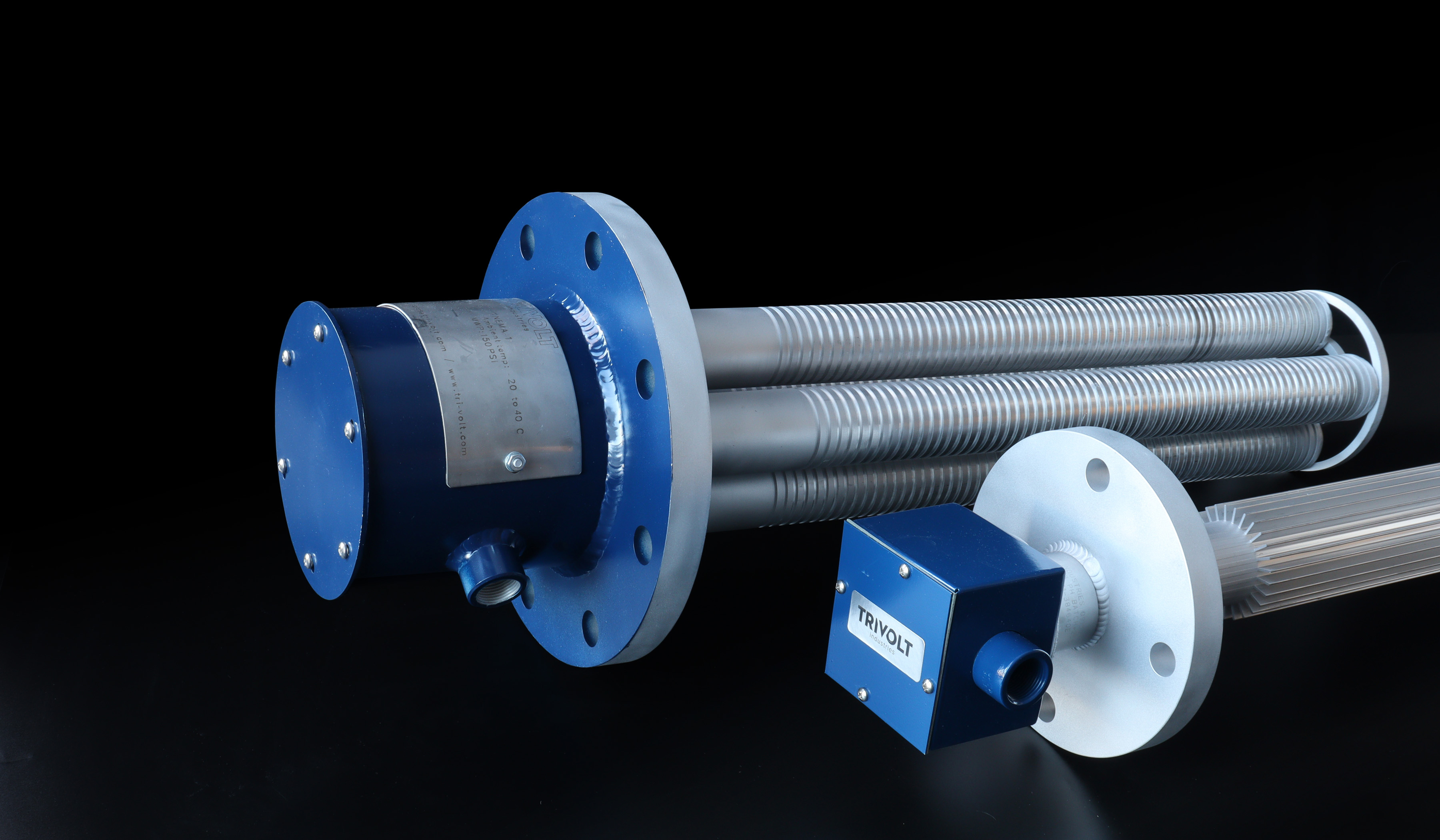

Circulation Immersion Heater

Circulation Immersion Heater

The Circulation Immersion Heater from TriVolt is designed to meet most application and site requirements. The units are designed to minimize heat loss through built-in ceramic fiber insulation installed in a stainless steel sheet housing.

Key Features:

- Versatile Material Options: Choose from aluminum, carbon steel, stainless steel, and titanium

- Innovative Design: Built-in ceramic fiber insulation to minimize heat loss

- Wide Range of Applications: Suitable for heating water, gas, air, steam, asphalt, and any fluids or compressed gases

- High Efficiency: Operates up to 600 volts in single or three-phase configurations

- Multiple Mounting Options: Available with flange mounting ranging from 2” to 10” and pressures from 150 to 300 PSI

- Compliance and Certifications: NEMA 1, 4, 7, 12 enclosures compliant with CSA-CUS and HazLoc certifications

Applications: The Circulation Immersion Heater is ideal for heating liquids such as air, oil, lube oil, transformer oil, heat transfer oil, and compressed gases. It can be used in both single and three-phase configurations with voltages ranging from 120V to 600V.

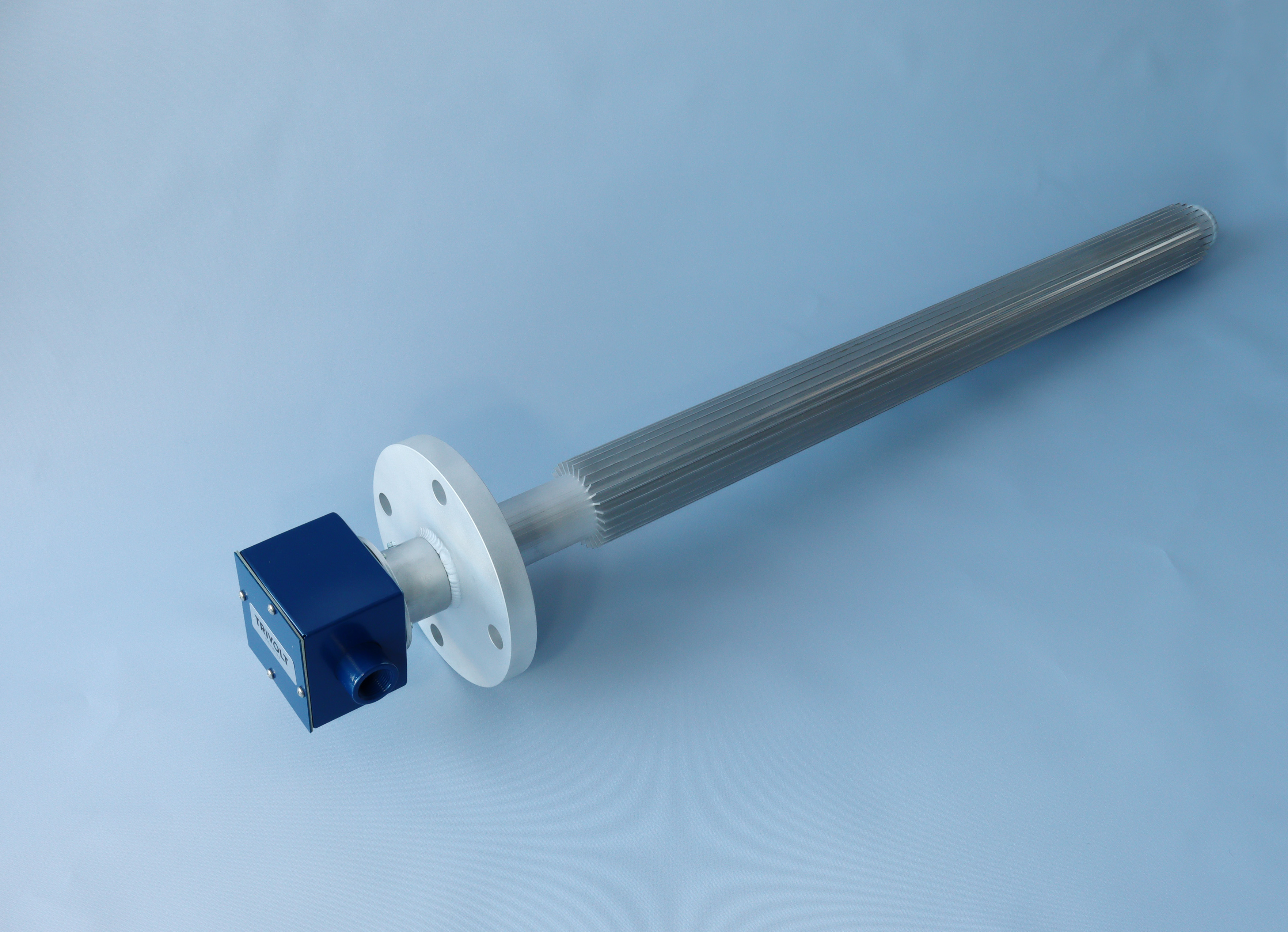

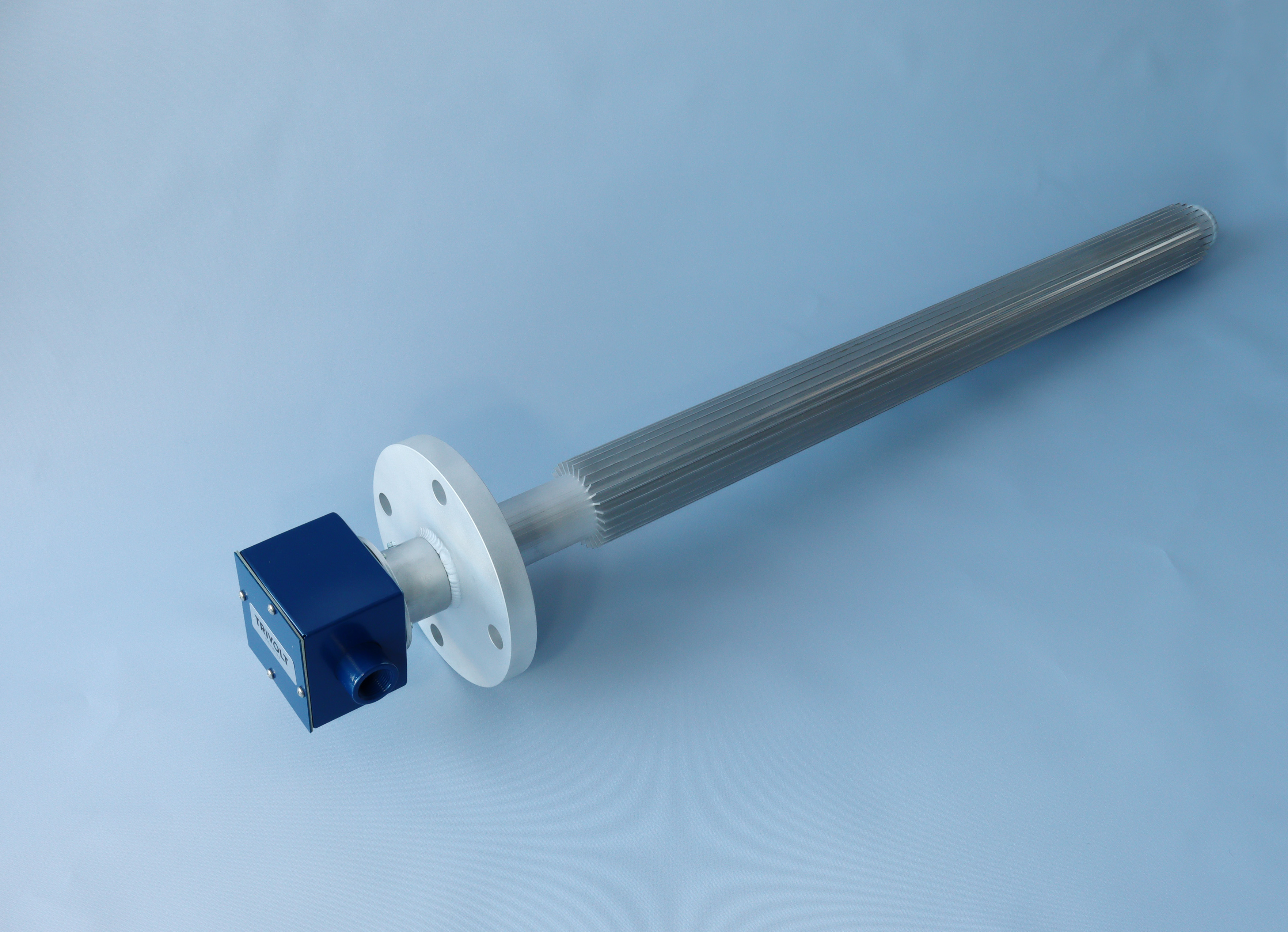

Aluma-Finned Immersion Heater

Aluma-Finned Immersion Heater

The Aluma-Finned Immersion Heater from TriVolt is designed for applications requiring low wattage density surface heating. The fins can be extruded or CNC-machined depending on the material chosen, increasing surface area per square inch while maintaining low watt densities on the surface.

Key Features:

- Versatile Material Options: Choose from aluminum, carbon steel, stainless steel, and titanium.

- Innovative Design: Extruded fins for aluminum and CNC-machined fins for other materials. 💡 𝗜𝗻𝗰𝗿𝗲𝗮𝘀𝗲𝗱 𝘀𝘂𝗿𝗳𝗮𝗰𝗲 𝗮𝗿𝗲𝗮 𝗲𝗻𝗵𝗮𝗻𝗰𝗲𝘀 𝗵𝗲𝗮𝘁 𝘁𝗿𝗮𝗻𝘀𝗳𝗲𝗿, making this design more efficient than traditional immersion heaters, resulting in 𝗲𝗻𝗲𝗿𝗴𝘆 𝘀𝗮𝘃𝗶𝗻𝗴𝘀 𝗮𝗻𝗱 𝗶𝗺𝗽𝗿𝗼𝘃𝗲𝗱 𝗽𝗲𝗿𝗳𝗼𝗿𝗺𝗮𝗻𝗰𝗲.

- Wide Range of Applications: Suitable for industries such as chemical, power, oil and gas, gas dryers, gas turbines, power, asphalt, and marine.

- High Efficiency: Operates up to 25W/PSI depending on application specifics.

- Multiple Mounting Options: Available with flange mounting ranging from 3” to 10” and pressures from 150 to 300 PSI.

- Compliance and Certifications: NEMA 1, 4 enclosures compliant with CSA-CUS and HazLoc certifications.

Industries & Applications

Pulp & Paper

Chemical

Power

Food & Beverage

Gas

Water Treatment

Plastic & Recycling

Pulp & Paper Industry Applications

Immersion style heaters are used in all hydraulic and lube oil reservoirs. They are typically used to replace original heaters that either did not provide enough wattage or failed. Their main purpose is to maintain the temperature of the lubrification oil, especially when the machine is idle.

Circulation style heaters are used for similar processes as immersion heaters. They are often seen on lube oil dehydrators, which are used in most pulp and paper mills. They can be supplied with Controls, Pumps, or as a complete skid.

TriVolt Finned Aluma Immersion heaters can be used in oil reservoirs that require high wattage heating for low-density applications. Tubular Immersion heaters can be used where density is less important, or where air or corrosive media flowing through a pipe requires heating.

Heat Trace Cables such as those manufactured in the Trivolt NoFreeze Product Portfolio can be used across the mill to prevent transmitters, flow meters, pipes, and tubes from freezing due to sudden drops in ambient temperatures.

Trivolt’s SSH Strip can be used in transformer and switch gear enclosures to drive out moisture. It is recommended to request application review by Trivolt for suitability)

Trivolt’s Duct Tubular Heaters can be used for heat and humidity control in electrical equipment rooms or forced air applications.

Trivolt’s Thermocouple can be used on boiler superheater tubes and other special applications.

Chemical Industry Applications

Immersion style heaters heat a fluid directly in a tank, vessel or container and are used to heat chemical storage tanks and process baths. They keep the chemical baths for plating at the right temperature, or to stay at a certain temperature for safe storage. Immersion heaters can also be installed in open tanks used to heat solutions to evaporate solvents and concentate a product.

Circulation style heaters allow precise and controlled heating of liquids or gases while they’re moving through a process line. They are typically used in maintaining temperatures of chemicals to react properly such as oils, solvents, water or more aggressive chemicals as they move through pipes. They help maintain viscosity of fluids, or prevent crystalization. Circulation heaters can be used to pre-heat materials before entering a process such as reactors, distillation or evaporators.

Heat trace cables are used to prevent pipes, tanks and vessels from freezing. Some chemicals reactions require stable thermal conditions, and these self-regulating cables keep chemicals at specific temperature to maintain viscosity, prevent crystallization, or avoid reactions.

Strip heaters are flat, rectangular heating elements mainly used for surface heating of metal plates or mounted to the outside of tanks, hoppers, or pipes to keep chemical at the right viscosity. They can warm up presses, molds, or mechanical parts used in manufacturing chemical products. They are used in drying ovens or systems where chemical-coated materials need to be dried at controlled temperatures. They reach high temperatures, distribute heat evenly, are easy to install, and can withstand harsh industrial environments.

Duct heaters are commonly employed to heat air or gases passing through ducts in processes like drying, curing, or preheating chemical compounds. They help remove moisture and assist in catalyzing reactions that require specific temperatures during the chemical production process.

Thermocouples are used in reactors, distillation columns, heat exchangers, and evaporators. They are accurate, have a fast response time, and can handle extreme conditions. Thermocouples are equipped with different types of connections; type K, J, or T depending on the chemical compatibility and temperature range used. Thermocouples are used in storage tanks to avoid spoilage or crystallization. They are used to monitor critical equipment such as boilers, furnaces, and incinerators. Thermocouples can be used in safety systems to help trigger rapid automated shutdowns to prevent explosions or toxic release of chemicals.

Ready to Experience the Trivolt Difference?

Contact us today to discuss your heating element needs and discover how our expedited services and efficient products can benefit your operations.